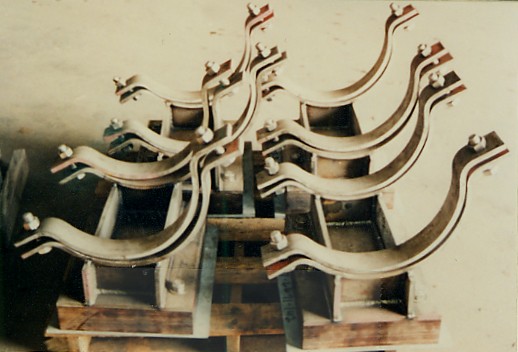

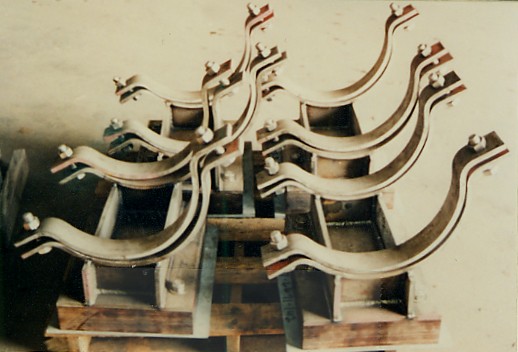

1,000 Standard Pipe Supports for Corrosive Environment

Piping Technology & Products, Inc., designed and fabricated over 1,000 standard pipe supports for a chemical agent disposal facility. These supports are to be used in a corrosive environment, therefore a unique, off white coating known as chemical resistant epoxy was used to cover the carbon steel, structural members.

The hardware was hot dipped galvanized, but in some cases, the u-bolts were coated with neoprene. Frames, guides, cantilever and axial stop supports comprised of the bulk of the material, however other support assembly components included rod hangers, clamped shoes and riser clamps.

Need pipe supports for your company? Get a pricing today!

Tags:

Structural Steel,

ASME/Miscellaneous Fabrication

Chrome-Moly Pipe Shoe for an 18" Pipe

Piping Technology & Products, Inc., designed and fabricated a Figure 700 chrome-moly shoe for an 18" pipe used to support high temperature lines at a power plant in Mexicali, Mexico.

The shoe's length is 12" and the pipe centerline distance was maintained at 17 3/8" from the bottom of the shoe. The clamp was designed at 1065°F and the load was designed for 6965 pounds. The base and clamp plates are made of A387 GR.22 plate material and the u-bolt parts are made of A193 GR.B7 bar stock.

Want to learn more about chrome-moly shoes and other products from Piping Technology and Products? Visit our webinar archives today!

Tags:

Guides and Anchors,

Pipe Shoes,

Fabricated Pipe Shoes

400 Lightweight, Vertical Constant Load Hangers

Piping Technology & Products, Inc. specially designed and fabricated four hundred 100-C, vertical constant load hangers for a plastics plant in Texas. The constants will be used to support a furnace standing three levels high.

In the plant (see image at left), thirteen single beams confined to limited space will each hang thirty constants, therefore PT&P engineers were required to design the constants to weigh less than 150 pounds. The 136-pound constants with travels of 10 inches upward and a supporting load of 950 pounds, are 33 7/8" in height and 8 7/8" in width. They are also supplied with shop prime, painted finish to safeguard against the extremely hot temperatures of the furnace area. In order to insure quality and proper operations of the constants, a prototype was built and tested to MSS standards.

Need some vertical constant load hangers? Let us price one for you today!

Tags:

Engineered Spring Supports,

Constants,

pipe hanger

66" Diameter, Three-bolt Pipe Clamp

66" Diameter, Three-bolt Pipe Clamp

Piping Technology & Products, Inc. custom designed and fabricated a 66-inch diameter, three-bolt pipe clamp for a chemical company located in Deer Park, Texas.

The clamp will be used in conjunction with a PT&P Spring Hanger and a length of rod in order to support the pipeline. After formation, the clamp's dimensions measured at 97.75 OAL and 69.5 at its widest point. By using a FEA program, the clamp was designed for an operating load of 24,000 pounds at 500° F. The materials used consisted of 1 ¾ x 10 x 128 ¼ thick A-36 Carbon steel, with three 2½ studs and nuts.

In need of some three-bolt pipe clamps? Request for pricing today!

Tags:

Clamp,

Support Assembly Components,

Pipe Clamp,

Three-Bolt Clamp

Stainless Steel Stanchions for a Power Company

Piping Technology & Products, Inc. provided 35 stainless steel stanchions for pipe sizes 4 to 18 inches for a power company in Alabama.

The ends of the stanchions have shop-cut end connections that will allow field welding without any modifications by site personnel. Some stanchions were provided with straight pipe connections and others were provided with elbow connections. The minimum height requirement provided for a centerline height equal to approximately 16" while the maximum pipe centerline was required to be at approximately 58 ½". The stanchions were designed at 1100°F and sustained a maximum design load of 18,000 pounds. The stanchion base plates are 304 stainless steel and the tubes are constructed of A240 GR.304 seamless pipe.

Do you need stanchions for your company? Request a quote and get a response within 48 hours!

Tags:

ASME/Miscellaneous Fabrication,

Stanchions

How to Size a Spring Hanger

Piping systems are used to transport gases, liquids and suspended solids between units of a plant. The temperatures of the contents and the pipe when the plant is in operation are often quite different from the ambient temperature of the surroundings. The heat transferred during changes in temperature causes metal pipe to expand and contract. Piping designers must provide for movement due to temperature changes and forces caused by pumps, gravity and other elements of the piping system.Read PT&P's "How to Size a Spring Hanger" Technical Bulletin for more information.

PT&P Specially Designs and Fabricates Constants for a Radiant-Tube Support System

These constants are an essential component of the radiant-tube support system for a reforming furnace. Piping Technology custom designed these units to fit in the limited space available inside the furnace. The bolting patterns for the constants needed to be flexible enough that they could be attached to the supporting structure with any of the support system designs being considered.

These constants are an essential component of the radiant-tube support system for a reforming furnace. Piping Technology custom designed these units to fit in the limited space available inside the furnace. The bolting patterns for the constants needed to be flexible enough that they could be attached to the supporting structure with any of the support system designs being considered.

Slide Plates: The "Sandwich" Concept

Piping Technology & Products, Inc. uses the "sandwich" concept when applying slide plates to our customers ' systems. Figure 1 shows a "sandwich" composed of two identical slide plates, one on top and another on the bottom. Each slide plate (which is like the bun of the "sandwich") and a low coefficient of friction material which is bonded to the metal backing plate.

Figure 1 (at left)

Figure 1 (at left)

In a typical application a slide bearing plate is welded to a structural steel member which is strong enough to provide the required support, but whose coefficient of friction is too high.

Figure 2 (at right) shows an application in which a slide bearing plate is welded on top of one steel beam supporting the other beam. When the top beam moves (due to thermal expansion, for example) it slides across the surface of the bearing plate without contacting the supporting another beam. To return to our "sandwich" metaphor, the top half of the "sandwich" is bonded to the sliding beam, and to the bottom half to the supporting beam.

Figure 2 (at right) shows an application in which a slide bearing plate is welded on top of one steel beam supporting the other beam. When the top beam moves (due to thermal expansion, for example) it slides across the surface of the bearing plate without contacting the supporting another beam. To return to our "sandwich" metaphor, the top half of the "sandwich" is bonded to the sliding beam, and to the bottom half to the supporting beam.

Want to learn more about spring hangers? Visit our webinar archives today!

Tags:

Slide Plates,

Constant,

Engineered Spring Supports,

Spring Hanger,

variable spring,

pipe hanger

Sway Braces for Petroleum Company in Louisiana

Piping Technology & Products, Inc. specially designed and fabricated ten sway braces, with total travel distance of 14, for a petroleum company in Louisiana.

The standard PT&P braces have springs that allow 3 of total travel distance. These sway braces were custom designed to provide total travel distance of 5 and 14. The center-to-center dimensions ranged from 92¼" to 115" with internal supports to prevent buckling. The desired spring rates for the sway braces were 450 lb./in. and 1350 lb./in. The custom sway brace assemblies comprised of pipes (for spring housing), springs (sizes dependent on spring rate and total travel) and in some cases, ball joints.

Do you need sway braces for an upcoming project? Request a price quote today!

Tags:

Shock Control,

Restraint & Support Devices,

Sway Braces

Pipe Shoes for a 14" Pipe at an LNG Plant

Pipe Shoes For 14" Pipe

Piping Technology & Products, Inc. fabricated

cryogenic pipe supports designed for a 14-inch pipe at a LNG plant in Algeria. The pipe operates below minus 50 degrees F, therefore the pipe supports were fabricated from three different materials in order to accommodate the low temperatures. The upper part, which clamps on to the pipe, was fabricated from a stainless steel plate that retains its strength at low temperatures. The middle section is a laminated phenolic block made from layers of wood impregnated under vacuum with a synthetic resin. A crossed orientation of the hard wood fibers is used to provide extra strength. The laminated phenolic block, which is a poor conductor of heat, was bolted to the bottom plate of the galvanized carbon steel.

Tags:

Guides and Anchors,

Pipe Shoes,

Fabricated Pipe Shoes

Big Ton Springs With Loads Up To 450,600 Newtons

Piping Technology & Products, Inc. specially designed and fabricated Big Ton Variable Springs for a chemical project in Canada. The supporting beams are 30" in length with PTFE, 25% glass filled stainless steel slide plates. The Big Ton Springs were designed with six coil springs with external guides to prevent horizontal twisting and internal guides to withstand horizontal friction forces. These units were also designed for operating loads from 260,000 to 350,000 Newtons and hydro-test loads from 300,000 to 450,600 Newtons. A total of six units were painted with a special finish specified by the client.

Need a big ton? Get pricing today!

Tags:

Big Ton Springs,

Big Tons,

Engineered Spring Supports,

pipe hanger