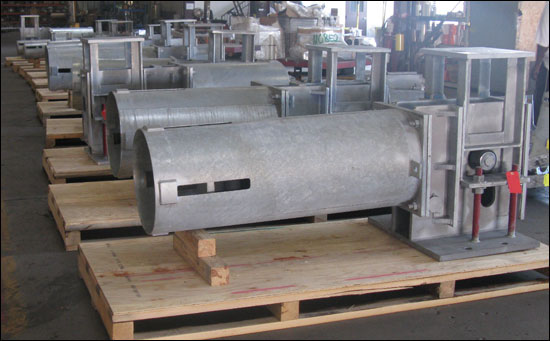

These 200 U-Type constant spring supports were modified to increase their installed height by adding a secondary plate and angles, which will be welded to the structural beam. The constants range in size from 25" to 27" in height, 52" to 67" in length, and 25" in width. Their load capacities range from 10,300 lb. to 13,000 lb. with vertical movement ranging from 3" to 4-1/2". All constants were fabricated from A-36 carbon steel, and went through standard load and travel testing per MSS Standards prior to shipment. Do you have a similar application that requires upthrust constants? Get pricing today!

The Pipe Support Blog

U-Type Constant Springs Designed for Large Travel for an Oil Refinery

These figure 200 U-type constant springs were fabricated from A-36 carbon steel and range in size from 30-1/2" to 41" in height, 25" to 31" in width, and 68" to 80" in length. These are horizontal constants designed to support piping from below where the base plate is bolted directly to the top of the steel or the foundation using anchor bolts. Loads range from 9,000 lb. to 42,000 lb., and vertical movements range from 6" to 11". All the constants went through standard load and travel testing per MSS Standards prior to shipment.

Want to learn more about constant springs? Instantly view a recording of a past webinar.

Subject: Constant Spring Supports Design and Application ** Webinar is worth 1 PDH Credit for TX Professional Engineers This Webinar is over... visit www.pipingtech.com/webinar to view the recording.

This Webinar will focus on the different types of constant spring supports. Learn about the special features available, in addition to the design of a constant support. View how the different cam/coil configurations produce a unique response to an applied load. Discover the step by step process used to size a spring for your application. Learn about the different attachments, testing, and installation and maintenance procedures. View examples of failed supports provided by our Field Service Division and learn why they failed and how to prevent it. Gain knowledge of the valuable tips used when deciding to adjust or replace a constant spring support, as well as shutdown and isolation procedures. The featured presenter, Jerry Godina has over 13 years experience as a pipe support designer and manages PT&P's engineer training development program. He also inspects existing supports, consults on site remediation projects and oversees installation on a regular basis.

Tags: Engineered Spring Supports, Constant Spring Supports, Constant Springs, Constants

These PT&P 200 series constants are fabricated from A36 carbon steel. The 200-A constants measure 18.5"w x 20"H x 65"L and will support a 22,200 lb. load. They are modified to avoid interference with the structure by shortening the frame. The 200-C constants measure 18.5"w x 29"H x 80"L and will support a 32,000 lb. load. The constants have specially fabricated lugs to allow for a 3 ton trolley to connect with it.

Do you have a need for constants in a current or upcoming project? Let us price them for you!

100-C Constants with Double Lug Suspension and Chained Travel Stops

100-C Constant Spring Supports with Double Lug Suspension

These figure 100 C-type constant springs were manufactured from A36 carbon steel for an oil refinery in Canada. Each constant was designed for 7" of travel with a load of 35,144 lb. They measure 21.5" W x 42" L x 80" H, and were specially designed to match a competitor’s dimensions in order to fit in the required application.

Do you require constant spring supports for your piping system? Get pricing today!

Tags: Engineered Spring Supports, Constant Spring Supports, pipe hanger

A "U-Type" and 6 "C-Type" constant spring supports were designed to support piping in a corrosive environment located off-shore in Malaysia. The U-Type measures 21" x 25" x 57" and C-Types range in size from 11-5/8" x 17" x 4" to 18-3/4" x 32" x 80".

A "U-Type" and 6 "C-Type" constant spring supports were designed to support piping in a corrosive environment located off-shore in Malaysia. The U-Type measures 21" x 25" x 57" and C-Types range in size from 11-5/8" x 17" x 4" to 18-3/4" x 32" x 80".

The constants are fabricated from A36 carbon steel with a fluorocarbon coating on the pins. The frame, housing, and all components were coated with a 3-coat paint system to resist corrosion. Standard load and travel tests were performed prior to shipping the constants on a rush basis.

Want to learn more about constant springs? Instantly view a past webinar on constants now!

Tags: Engineered Spring Supports, Constant Spring Supports, pipe hanger

Ever wonder what makes a constant spring support different from a variable spring support? How does each one function? How do they support loads and allow for movement in a pipeline? Check out our new spring support article that provides all the answers to these questions and more.

F-Type Variable Springs with Slide Plates

Upthrust 200-U Type Constants for an Oil Refinery

Want to learn more about constants? Instantly view a past constants webinar now!

Tags: Engineered Spring Supports, Constant Spring Supports, Variable Springs, pipe hanger

Original Supports (not fabricated by PT&P)

PT&P received a call to inspect spring supports in operation at a salt water cooler tower. It was quickly determined that replacement supports would be needed due to the heavy corrosion of the original supports not fabricated by PT&P.

Neoprene Coated Fig. 200 U-Type Upthrust Constant Spring Supports

A total of 40 constant and variable spring supports were fabricated as replacements. Each support was sealed with a neoprene coating over a hot-dip galvanized finish instead of stainless steel. This type of finish will ensure a much longer life-span. The spring supports ranged in loads from 800 lb. to 15,000 lb. with various travel ranges.

Neoprene Coated Fig. 100 U-Type Upthrust Constant Spring Supports

Do you need to replace some springs in your plant? Contact us for a quote today!

Tags: Engineered Spring Supports, Replacement Constants, Constant Spring Supports, pipe hanger

More helpful instructional videos are available on our website!

Tags: installation, Engineered Spring Supports, Constant Spring Supports, Uncategorized, Constants, pipe hanger, maintenance

Special U-Type Constant Spring Supports

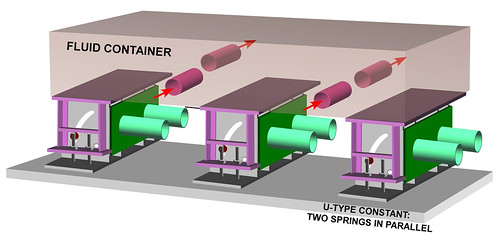

PT&P designed a constant load support system for a fluid tank with a load of 105,000 lb. over an area of 5' W x 20' L. To prevent twisting of the fluid container, the support system is designed to allow for “level” vertical movement. This was achieved by using a special system composed of three U-Type constant units. Each unit employs two springs working in parallel with a common large base plate and a load flange to support the entire 5' width of the container.

Special U-Type Constant Spring Supports

The constants will support loads of 39,000 lb., 36,000 lb., and 30,000 lb., with a total travel of 4" in the “upwards” direction. The spring coils were coated in neoprene, and all the other major components were hot dip galvanized to inhibit corrosion. These constants were constructed primarily from carbon steel with the use of stainless steel and PTFE, 25% glass filled slide plates.

Want to learn more about constant springs? Instantly view a past constant webinar today!

Tags: Engineered Spring Supports, Constant Spring Supports, pipe hanger