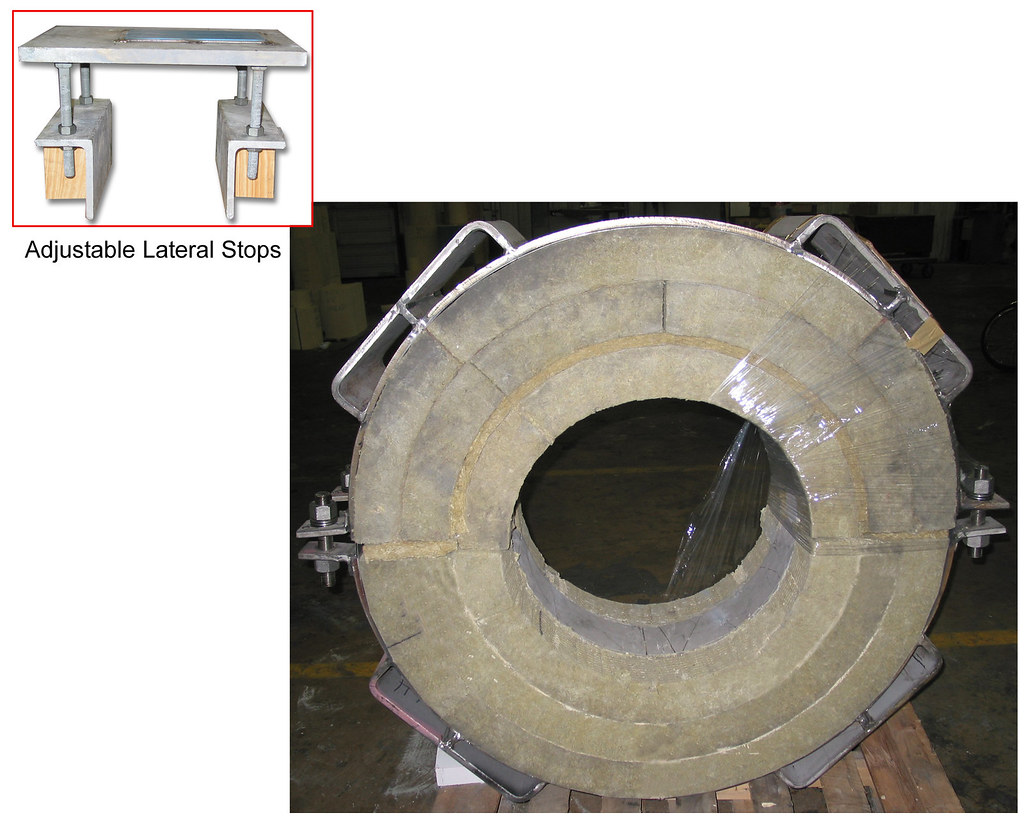

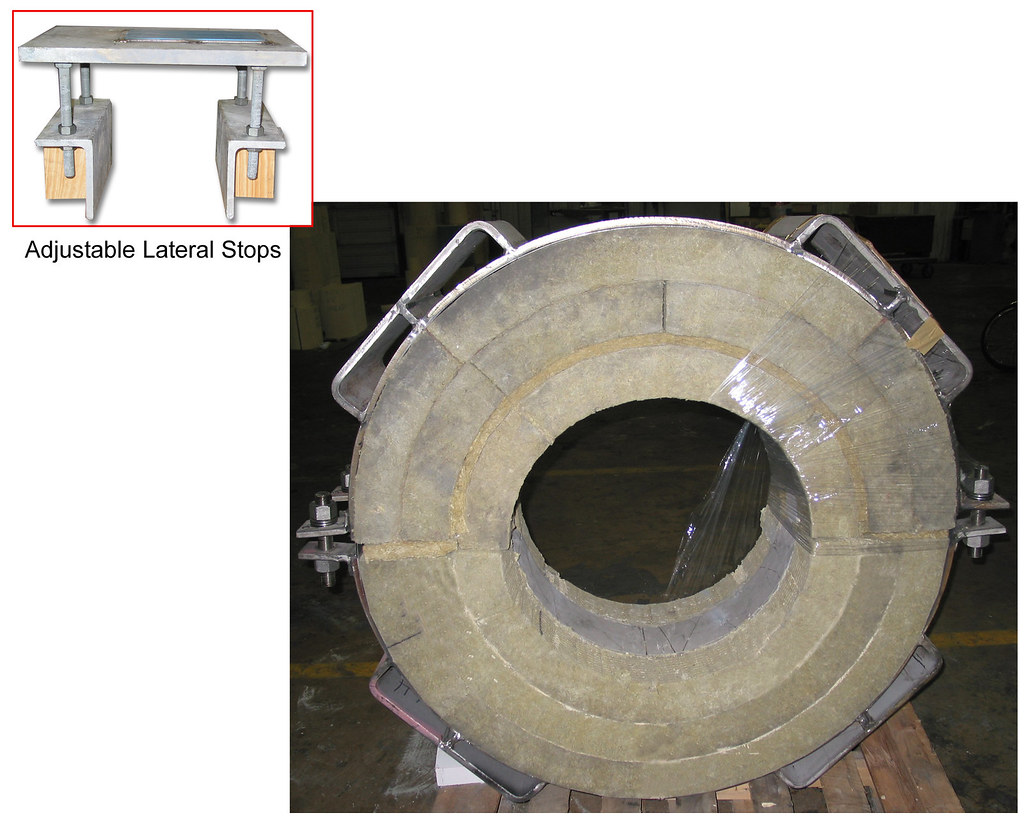

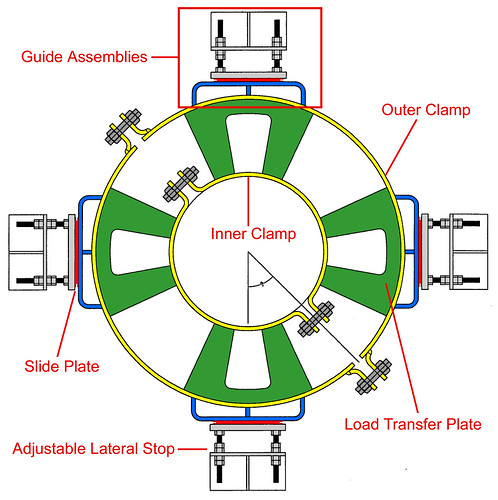

6000 lb. Load Hot Shoe with Adjustable Lateral Stops

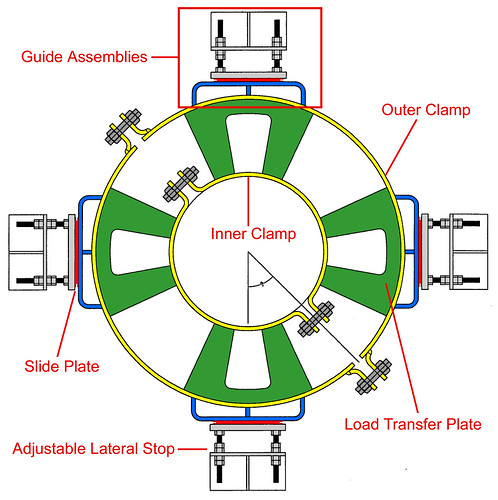

Drawing of Custom Hot Shoe

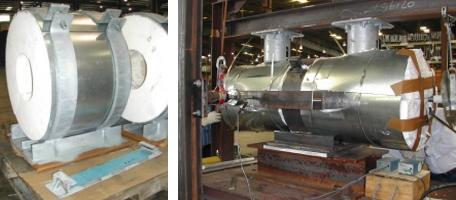

Piping Technology & Products, Inc. recently assisted in the design and fabrication of a special hot shoe with adjustable lateral stops for an oil refinery in LA. The shoe assembly is designed to support loads up to 6000 lb. and to guide pipes that may reach up to 1200°F. The hot shoe consists of a 12 thick mineral wool insulation, an inner clamp surrounded by four load transfer plates, an outer guiding clamp, and four guide assemblies with PTFE, 25% glass filled, slide plates. The load transfer plates provide support and prevent damage to the insulation between the inner and outer guiding clamp.

The guide assemblies (comprised of the four guides on the shoe and the adjustable stops) are designed to account for lateral, vertical, and axial movement. PTFE, 25% glass filled, slide plates are used to minimize friction caused by movement between the shoe and the adjustable stops. The adjustable stops are fabricated from a 1 x 12 x 19 carbon steel plate with four rods and two angles. These allow for flexibility in adjusting the distance/gap within each guide assembly to control movement.

Want to learn more about hot shoes? Watch a pre-insulated support webinar now!