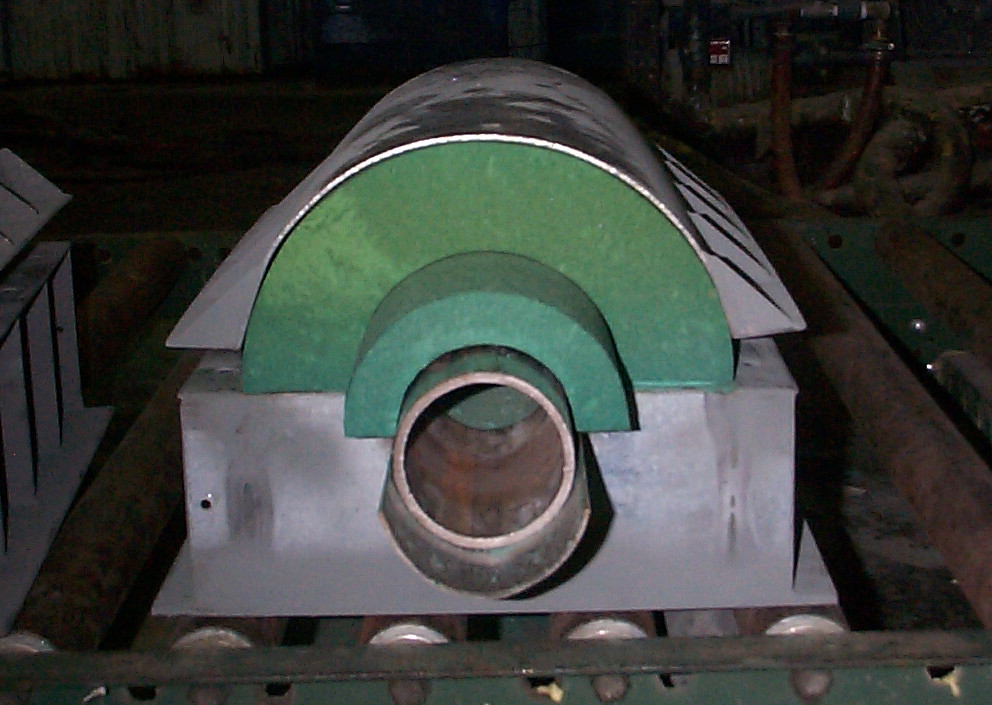

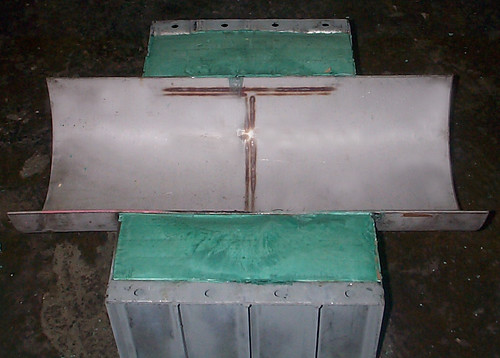

Check out our most recent article that looks at the history of insulated pipe supports through the past 100 years. Learn about the developments made in the 1950's and 1960's that introduced the use of "Foam Glass", a lightweight material that is manufactured primarily from recycled glass and used in the design of insulated pipe supports. Later, polyurethane was developed to provide greater load carrying capabilities. Read the full article on the:

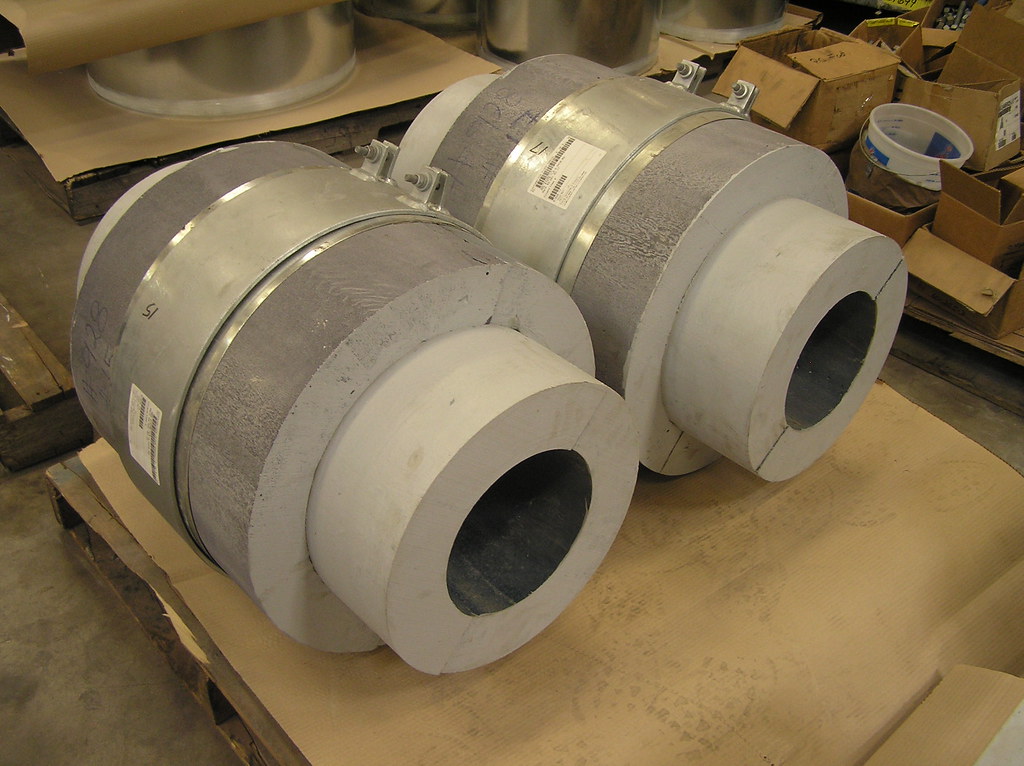

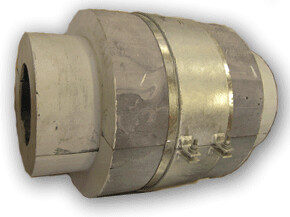

Permali Insulated Pipe Anchors

Want to learn more about pre-insulated supports? Instantly view a past pre-insulated support webinar now!