Follow these 7 steps below to maintain and extend the life span of your hydraulic snubber.

1. Observe the fluid level to make sure there is sufficient fluid for the snubber to operate

2. Check for leaks - If the fluid level is decreasing, determine the cause and effect remedial action.

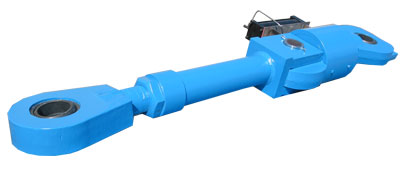

3. Check the condition of the load pins and spherical ball bushings. Apply a high pressure grease for long-term benefits.

4. Check the condition of the exposed portion of the piston rod. Check for scoring, paint or other physical damage.

5. Check the condition of the piston rod wiper. Verify that it's in position and working effectively.

6. Check for evidence of abuse like welding arc strikes, bent or dented parts, scratched paint, etc.

7. Finally, check the overall physical appearance. This encompasses all of the above.