Constants For Constricted Areas of a Chemical Processing Plant

Piping Technology & Products, Inc. custom designed and fabricated 200-C type constants to suit constricted areas of a chemical processing plant in Texas.

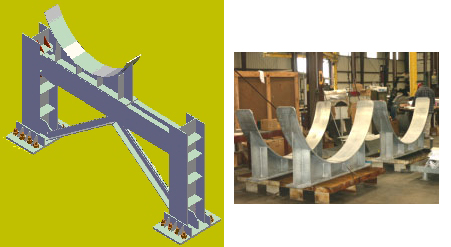

Short distances between the pipe and the supporting beam necessitated a custom design. Two designs were needed one was for a 230 lb. load with 11"down travel, while the other was for a 260 lb. load with 13-1/2" down travel. The PT&P standard design for these constants has Take-Out values of 19-9/16" and 21-9/16", respectively. However, the available space permitted no more than 9-1/2".

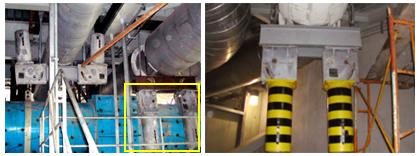

Compare the final design, shown on the left to the standard design, shown on the right. Note that the lower part of the frame has been cut away, permitting the pipe to move nearer to the constants' supporting lugs.

PT&P's system of stock pipe and spring supports, allowed engineers and workers to fabricate these constants within a short amount of time.

Find out more information about constants in our webinar archives!