Slide plates are easy to maintain if you follow these certain steps when inspecting them. Visit our visual media section to learn what four steps to take for Slide Plate Inspection and Maintenance. Our field service manager, David Baker, will show you what to look for when inspecting your PTFE slide plates. If you have any questions, feel free to call David Baker at 713-992-7048 or email us at info@pipingtech.com.

The Pipe Support Blog

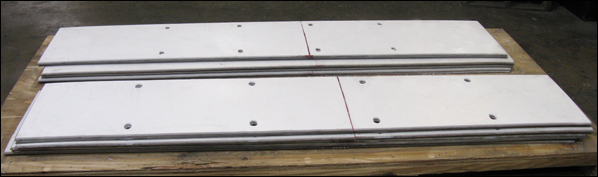

PTFE, 25% Glass Filled Slide Plates Bonded to Steel Backing Plates

The slide plates are comprised of 1/4" thick PTFE, 25% glass filled slide plates bonded to 1/8" A240 grade 316 L stainless steel backing plates. Stainless steel was used for better resistance to corrosion and longevity. The assemblies measure 83" long by 20" wide and will be installed underneath a bridge. A total of 16 slide plates were fabricated and designed for a pressure of 500 psi at ambient temperature. PTFE, 25% glass filled material provides a low coefficient of friction, is easy to install, does not require surface treatments, or grouting, and is unaffected by weather conditions.

Would you like to learn more about slide plates? Check out a recording of our past slide plate webinar!

24" Bolted Clamp Pipe Shoe with Slide Plates for a Piping System

These customized bolted clamp pipe shoes with PTFE, 25% glass filled slide plates were fabricated for a radiant syngas cooler piping system in Indiana. The supports were designed for 24" diameter piping with a pressure of 2,256 psig at 350°F. The axial displacement is +/- 1.326" facilitated by slide plates on three quadrants. These pipe shoes were custom designed and fabricated entirely from carbon steel with a hot-dipped galvanized finish.

Do you have a requirement for bolted clamp pipe shoes? Let us price it today.

Tags: Slide Plates, Guides and Anchors, Pipe Shoes, Fabricated Pipe Shoes

Custom Variable Spring Supports with Stainless Steel Slide Plates

This custom designed variable spring assembly is comprised of a standard PTP-1-160 type F variable spring with a supplementary extension and load flange with a stainless steel slide plate. The variable is fabricated entirely from carbon steel with a hot-dipped galvanize finish. The extension is schedule 40 pipe, 8" in diameter and 12-5/16" in height. The slide plate is fabricated from A240 grade stainless steel and is welded to the top of the load flange. This support will be used underneath a 16" diameter pipe with a dummy leg. It is designed for 1/16" vertical travel and 1/8" horizontal travel for an oil refinery in Algeria.

Do you require custom variables or slide plates for your piping system? Get pricing today!

Tags: Variable Spring Assemblies, Slide Plates, Engineered Spring Supports

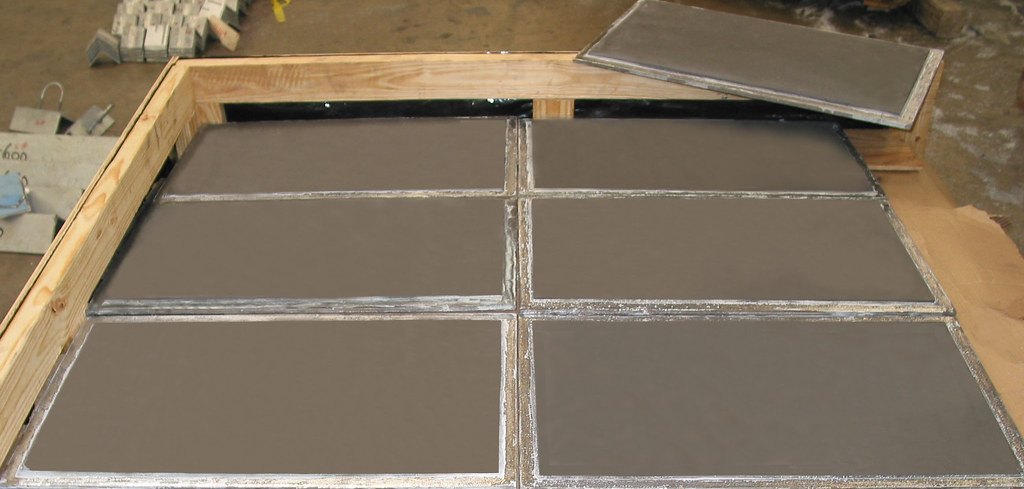

The slide plate assembliesare fabricated from stainless steel, phosphorus bronze, and carbon steel. The 2" thick carbon steel base plate is securely anchored to a concrete foundation, and the stainless steel slide plates are affixed to the base plate by countersunk attachment bolts. The phosphorus bronze slide plates, with machined grooves on the underside are placed on top of the stainless steel plates.

|

|

To allow for lubrication between to the contact surfaces of the two slide plates, grease is added through a fitting on the side of the bronze slide plate. The fitting allows access to a channel in the center of the bronze slide plate that leads to the grooves. A hole is located in the 2" thick base plate to allow for grout to be poured through after installation.

Want to learn more about slide plates? View a recording of a past slide plate webinar!

PT&P was contracted to assist in the determination of pipe support maintenance at a power plant in Texas. The constant effort support springs with loads of excess of 9,500 lbs and the variable spring supports with loads of 450 lbs were marked for needing attention.

Cleaning Variable Spring Unit

Inspecting Variable Springs for Performance

PT&P's objectives were to:* Evaluate the pipe supports

* Determine state of performance

* Provide a plan of action

* Train personnel on-site to perform adjustments and replacement of supports or support components

* Provide final inspection of modified supports

After Cleaning & Preparation of the Constant

Final Assembly with Added Slide Plates

The pipe supports needing attention could not be set to the required installation position. A plan was initiated to recondition some of the support components such as turnbuckles and rods. This would allow a greater range of field adjustment to the pipe supports. During a planned shut-down, PT&P Field Service Units returned to the site to modify the existing supports. The initial phase of the modifications included bracing the piping in order to isolate and lock the supports in position. Then, they were disconnected from the system and modifications to the assemblies were completed. Afterwards, the supports were reinstalled and any necessary adjustments were completed. A total of eight pipe supports were modified or adjusted.

Roller Bearing Needing Maintenance

Restored Roller Bearing

Do you see a need for a routine inspection of your plant? Contact us for a quote today!

Tags: Pipe Support Field Services, Slide Plates, Engineered Spring Supports, Constant Springs, Variable Springs, pipe hanger, field service

Piping Technology & Products, Inc. recently custom designed and manufactured 32 spring supports with PTFE, 25% glass filled, slide plates for a plant in China. The total weight of the spring supports supplied is 13,143 lbs. and they have a travel range of ¾”. These products support the vessel and the PTFE, 25% glass filled, slide plates allow height adjustment as well as mobility. These spring supports are designed for operating loads of 42,266 lbs. and were constructed of carbon steel.

Do you require spring supports or slide plates in your piping system? Get pricing now!

Tags: Slide Plates, Engineered Spring Supports, PTFE 25% Glass Filled, Variable Springs, pipe hanger

The Bronzphite® slide plates shown above are constructed from graphite and phosphorus bronze with dimensions ranging from 3" x 3" to 6" x 36". They are designed for up to 500ºF and a total travel of up to 30".

In general, Bronzphite® is a self-lubricating bearing plate made of a high quality bronze with graphite filled grooves. The solid graphite inserts are arranged in various patterns and sizes to meet customer specifications. This type of slide plate is best suited for high loads, low velocity applications and in places where the use of oil or grease in undesirable or unfeasible.

Want to learn more about slide plates? View a past slide plate webinar now!

Tags: Slide Plates, Bronzphite®

13,900 lb. Load Pipe Shoes and Bronzphite® Slide Plate

Piping Technology and Products, Inc. recently designed and fabricated more than 75 pipe shoe and Bronzphite® slide plate assemblies for an oil refinery in Texas. Each assembly consists of two pipe clamps, a base plate and a maintenance free Bronzphite® slide plate. The pipe shoes with sizes ranging from 18 to 24 are fabricated from A387 alloy steel. They are designed for 965°F and 2 of horizontal movement.

The 3 x 3 Bronzphite® (graphite impregnated bronze) slide plates are self-lubricating bearing plates made of a high quality bronze with graphite filled grooves. They are designed for heavy loads, low velocity applications, and for situations where the use of oil or grease is undesirable or unfeasible.

Do you require pipe shoes or slide plates in your piping system? Let us price them for you today!

Tags: Slide Plate, Slide Plates, Bronzphite®

61" x 61" Graphite Slide Plates for a Refinery Project in India

PT&P designed and fabricated eighteen graphite slide plates for a refinery project in India. These plates are made of graphite sheets with thicknesses of 6mm and 12mm. The overall dimensions of the plates are 3/8" x 19-11/16" x 19-11/16" and 3/8" x 61" x 61". The plates will be tack welded on top of big ton spring supports in the refinery to minimize frictional effects.

Do you see a need for slide plates in your piping system? Let us price them for you today!

Tags: Graphite, Slide Plates