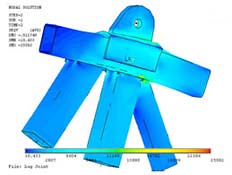

The structural pipe supports are fabricated from carbon steel and coated with red oxide primer. The structural steel will be stored in a warehouse for several months while the power plant is being built. Due to the plant's location along the United States East Coast, the use of the red oxide primer was selected. Also, modifications were made to our standard "insulation saddles" to allow for a higher load capacity; which can be seen in the foreground of the image above.

Do you require replacement or additional structural supports in your plant? Get a quote today!