This Webinar is over... visit www.pipingtech.com/webinar

Subject: Constant Spring Supports Design and Application Webinar ** Webinar is worth 1 PDH Credit for TX Professional Engineers

Date: Thursday, January 19, 2012

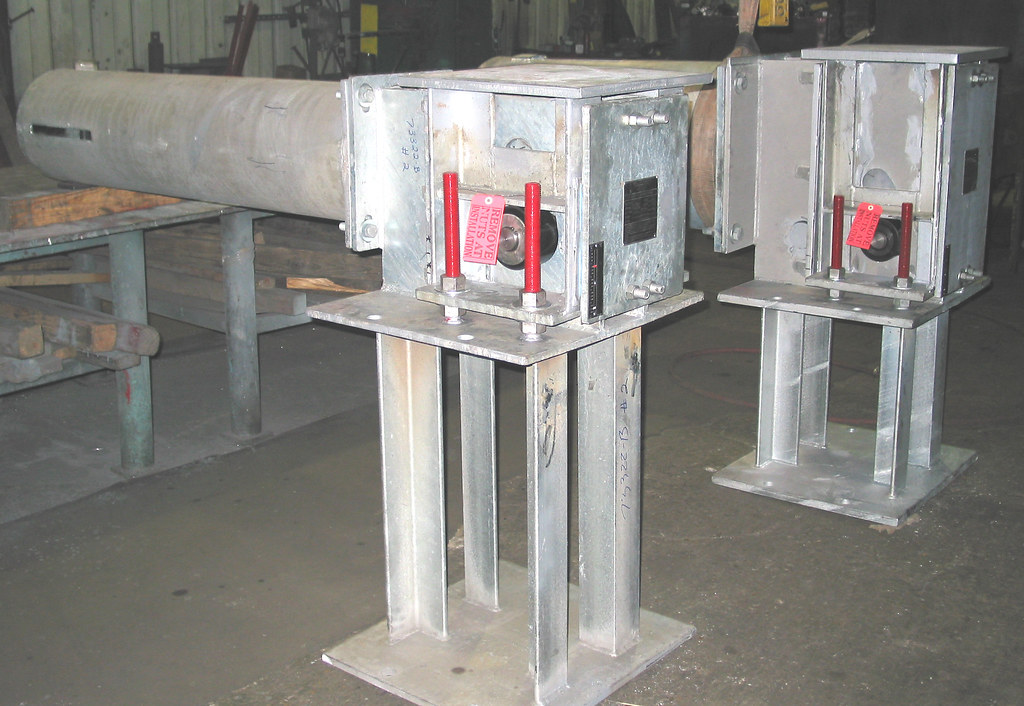

This Webinar will focus on the different types of constant spring supports. Learn about the special features available, in addition to the design of a constant support. View how the different cam/coil configurations produce a unique response to an applied load. Discover the step by step process used to size a spring for your application. Learn about the different attachments, testing, and installation and maintenance procedures. View examples of failed supports provided by our Field Service Division and learn why they failed and how to prevent it. Gain knowledge of the valuable tips used when deciding to adjust or replace a constant spring support, as well as shutdown and isolation procedures.

This Webinar will focus on the different types of constant spring supports. Learn about the special features available, in addition to the design of a constant support. View how the different cam/coil configurations produce a unique response to an applied load. Discover the step by step process used to size a spring for your application. Learn about the different attachments, testing, and installation and maintenance procedures. View examples of failed supports provided by our Field Service Division and learn why they failed and how to prevent it. Gain knowledge of the valuable tips used when deciding to adjust or replace a constant spring support, as well as shutdown and isolation procedures.The featured presenter, Jerry Godina has over 13 years experience as a pipe support designer and manages PT&P's engineer training development program. He also inspects existing supports, consults on site remediation projects and oversees installation on a regular basis.