Special U-Type Constant Spring Supports

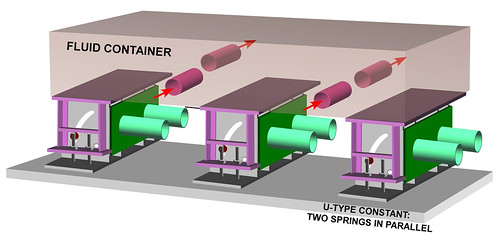

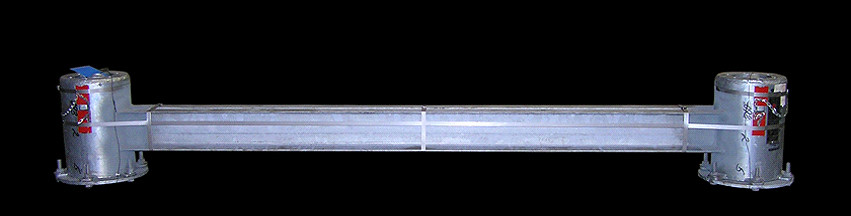

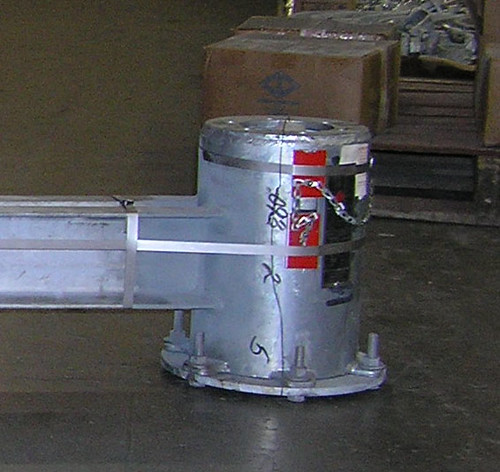

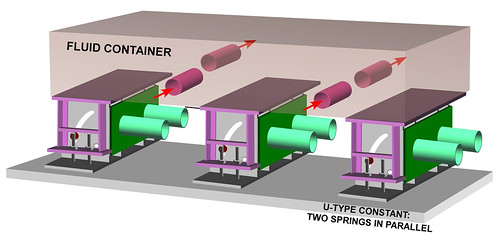

PT&P designed a constant load support system for a fluid tank with a load of 105,000 lb. over an area of 5' W x 20' L. To prevent twisting of the fluid container, the support system is designed to allow for “level” vertical movement. This was achieved by using a special system composed of three U-Type constant units. Each unit employs two springs working in parallel with a common large base plate and a load flange to support the entire 5' width of the container.

Special U-Type Constant Spring Supports

The constants will support loads of 39,000 lb., 36,000 lb., and 30,000 lb., with a total travel of 4" in the “upwards” direction. The spring coils were coated in neoprene, and all the other major components were hot dip galvanized to inhibit corrosion. These constants were constructed primarily from carbon steel with the use of stainless steel and PTFE, 25% glass filled slide plates.

Want to learn more about constant springs? Instantly view a past constant webinar today!