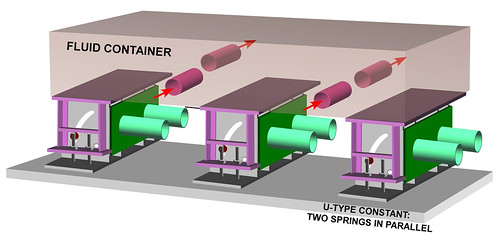

Piping Technology & Products, Inc. Performed Field Services for a Power Generating Plant in TexasPT&P was contracted to assist in the determination of pipe support maintenance at a power plant in Texas. The constant effort support springs with loads of excess of 9,500 lbs and the variable spring supports with loads of 450 lbs were marked for needing attention.

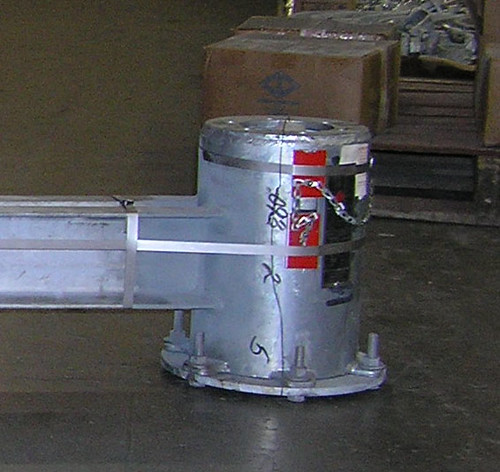

Cleaning Variable Spring Unit

Inspecting Variable Springs for Performance

PT&P's objectives were to:

* Evaluate the pipe supports

* Determine state of performance

* Provide a plan of action

* Train personnel on-site to perform adjustments and replacement of supports or support components

* Provide final inspection of modified supports

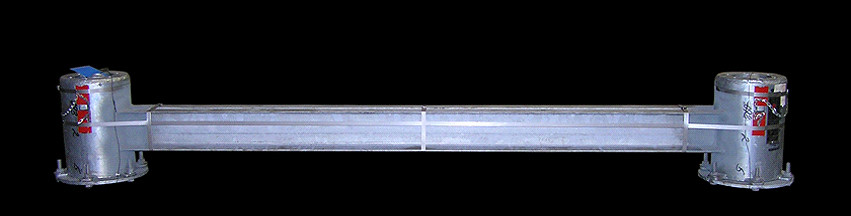

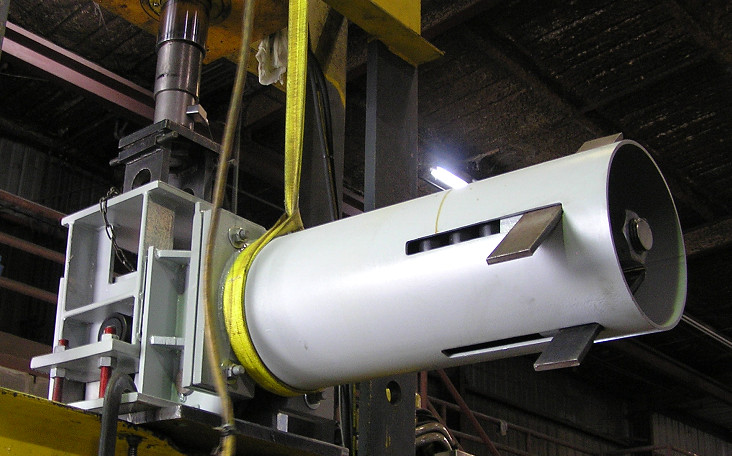

After Cleaning & Preparation of the Constant

Final Assembly with Added Slide Plates

The pipe supports needing attention could not be set to the required installation position. A plan was initiated to recondition some of the support components such as turnbuckles and rods. This would allow a greater range of field adjustment to the pipe supports. During a planned shut-down, PT&P Field Service Units returned to the site to modify the existing supports. The initial phase of the modifications included bracing the piping in order to isolate and lock the supports in position. Then, they were disconnected from the system and modifications to the assemblies were completed. Afterwards, the supports were reinstalled and any necessary adjustments were completed. A total of eight pipe supports were modified or adjusted.

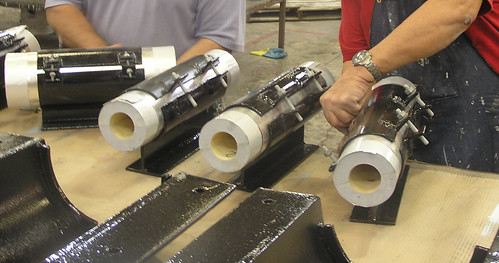

Roller Bearing Needing Maintenance

Restored Roller Bearing

Do you see a need for a routine inspection of your plant? Contact us for a quote today!