200 U-Type Constants with 46" of Travel

Inspecting the Constant Spring Supports

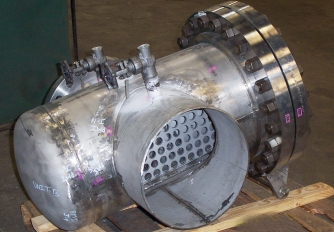

Piping Technology & Products, Inc. recently designed and manufactured 200 U-Type upthrust constants for a geothermal plant in Hawaii. The constant pictured on the left has frame dimensions of W 40" x H 75" x L 142", a constant load of 9,888 lb. to 10,239 lb. and a design travel of 46". It also utilizes rollers and PTFE, 25% glass filled slide plates to reduce the friction resulting from axial movements. All the constants in this project are composed of A36 carbon steel. Standard load testing and travel testing were conducted prior to shippment.

Do you require custom constants like those described above? Let us price them for you today!