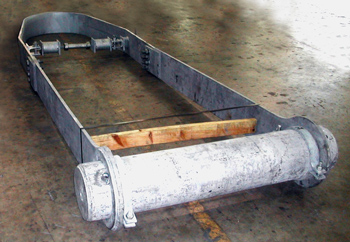

Pipe Saddles for a Refinery in Chad

Piping Technology & Products, Inc. designed and manufactured these pipe saddles for a power plant in Chad.

The saddles are comprised of bolt clamps, structural steel and vinyl pipe shields. They were built for bare pipes ranging in size from 2 24 and can accommodate temperatures from 29 degrees C. to 538 degrees C.

Do you see a need for pipe saddles in your plant or refinery? Let us price them for you today!