Variable Springs with Permanent Adjustment Travel Stops

Piping Technology & Products designed and manufactured these variable springs with permanent adjustment travel stops for a refinery in Texas.

These types of travel stops are used to allow ease of installation, provide a means for field load adjustment within the working range of the spring, and allow the springs to be "locked" easily whenever they are taken out of service for shutdowns or refurbishment of the system.

For this requisition, a total of 23 variable springs with adjustable travel stops were fabricated. The springs are made from carbon steel and the adjustment rods are made from A-325 high strength bolt material. The springs ranged in size from PTP-1-60-F to PTP-2-180-F size spring. The largest springs were set for an operating load of 12,900 lbs. and a hydrotest load of 14,000 lbs. and a maximum travel of ½. All of the springs were tested in the load cell to insure proper operation. Per the customer's request, these springs were supplied at an expedited delivery of 3 weeks.

Want to learn more about variable springs? View a past variable spring webinar instantly!

Tags:

Engineered Spring Supports,

Variable Springs,

pipe hanger

Sway Struts for a Construction Company

Piping Technology & Products, Inc. recently designed and manufactured Sway Struts, PT&P Fig. 2110, with clamps for a construction company in Indiana.

The overall length of the support assemblies range from 24” to 60” and have loads ranging from 3,500 to 11,630 lbs. The sway strut assemblies are made of carbon steel and are used to restrain movement of piping in one direction while providing for movement due to thermal expansion or contraction in another direction.

Do you require sway struts in your current or future project? Get pricing today!

Tags:

Shock Control,

Restraint & Support Devices,

Sway Strut

Bronzphite® Slide Plates

These ½ x 7 x 12 Bronzphite® slide plates were bolted to a 2 ¾ x 11 x 16 backing plate with a 5mm recess. The recess allowed the Bronzphite® plates to be countersunk and bolted to the backing plates. The Bronzphite® plates were designed to withstand 14Mpa working compression and a maximum temperature of 230˚F.

Do you have a need for slide plates in your piping system? Let us price them for you today!

Tags:

slide bearing plates,

Slide Plates,

Bronzphite

51,000 lb. load Hot Shoes for a C4 Olefins Complex

Piping Technology & Products, Inc. designed and manufactured 44 pipe shoes consisting of six guided and axial hot shoes, 10 guided hot shoes, and 28 sliding hot shoes. The materials used were calcium silicate, Marinite®, stainless steel plates, and PTFE, 25% glass filled. These shoes were designed for 8" pipe with 7" insulation with a load capacity of 5,100 lbs.

Do you require hot shoes in your piping system? Get pricing today!

Tags:

Hot Shoes,

Pre-Insulated Pipe Supports

Hot Shoes for a Chemical Plant in Texas

Piping Technology & Products, Inc. designed and manufactured 60 Marinite® hot shoes for a chemical plant in Texas.

These hot shoes are composed of Marinite®(high-density calcium silicate) and carbon steel. They were made for 8 NPS with 7 insulation. These shoes are used on steam lines, effluent lines, and any other process lines where it's imperative that thermal energy is not lost through the pipe support. Tests were performed to show outer skin temperature at operating conditions.

Want to learn more about hot shoes? Instantly view a pre-insulated pipe support webinar today.

Tags:

Hot Shoes,

Pre-Insulated Pipe Supports

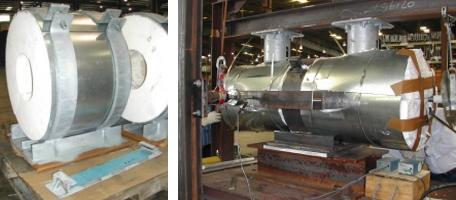

116,500 lbs. Load Big Ton Springs for a Petrochemical Plant

Piping Technology & Products, Inc. designed and manufactured 4 identical Big Ton springs for a petrochemical plant in Texas.

These 66 x 18 x 14.5 Big Ton springs are made of A-36 carbon steel and have a design suitable for temperatures up to 750 degrees F. They have a hot load capacity of 116,500 lbs and a cold load capacity of 94,500 lbs. Load tests were performed to ensure that the springs could safely sustain the specified design load. Applicable travel was ½ downward, but design travel ranges up to 6.

Want to learn more about big ton spring supports? View an engineered spring support webinar today!

Tags:

Big Ton Springs,

Engineered Spring Supports,

pipe hanger

Pipe Stanchions and Beams for a Power Center

Piping Technology & Products, Inc. designed and manufactured carbon steel and alloy pipe stanchions for a power center in Arizona. PT&P also produced carbon steel beams for the project.

These stanchions are made to fit Extra Strong and Standard pipes, which are 3-12 in size. Figure 1 shows the stanchions and beams for this job before they were coated with a green primer and prepared for shipment.

Do you see a need for stanchions and structural steel beams in your power plant or refinery? Get pricing today!

Tags:

Support Assembly Components,

Stanchions,

Beams

Various Sized Pipe Saddles for a Power Project

Piping Technology & Products, Inc. designed and manufactured pipe saddles for a power project in California.

The pipe saddles were built for 12", 24" and 30" pipe and the loads varied from 1,500 pounds to a maximum design load of 20,000 pounds. The saddle and its components will hang from a beam in the field by spring hangers to complete what is known as a "trapeze" pipe hanger assembly. In order to prevent movement, the supported pipes will be secured to the curved portion of the saddle with u-bolts.

If you are in need of pipe saddles, let us know! We would be glad to help you.

Tags:

Saddle Support,

Pipe Saddles,

Support Assembly Components

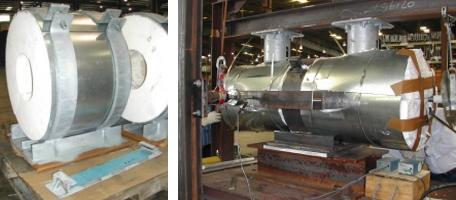

Piping Technology & Products, Inc. specially designed and fabricated big ton springs equipped with special rollers to accommodate moving apparatuses and support piping at a refinery in India.

Piping Technology & Products, Inc. specially designed and fabricated big ton springs equipped with special rollers to accommodate moving apparatuses and support piping at a refinery in India.

The specially designed big tons were made to support loads ranging from 55,000 lbs. to 114,000 lbs with no more than 5/16" upward movement. Its composition comprises of A-36 carbon steel, built to a maximum height of 23-5/8".

The special rollers installed on the top (see photo at top right) of the load flange, keeps the aforementioned loads moving smoothly under all kinds of conditions. To further assure their quality, each of the big ton spring assemblies underwent load testing and afterward were hot dipped galvanized to prevent against corrosion.

Want to learn more about big tons? Visit our webinar archives today!

Tags:

Big Ton Springs,

Big Tons,

Engineered Spring Supports,

pipe hanger

Big Ton Springs Equipped with Lifting Lugs

Piping Technology & Products, Inc. specially designed and fabricated big ton springs equipped with side lifting lugs to support piping of a 102-megawatt, refinery cogeneration power plant in California.

Under typical circumstances, this type of job application would utilize variable spring hangers, but because of the restricted space, the hangers' size would be too small to support a hot load of 19,068 lbs and cold load of 17,212 lbs. In order to satisfy both the required loads and space, PT&P engineers designed and fabricated figure 500 big ton springs equipped with side lifting lugs. The lifting lugs were attached to allow the big ton to suspend as a variable spring would in the field.

Are big ton springs a necessity for your next project! Request a quote today!

Tags:

Big Ton Springs,

Big Tons,

Engineered Spring Supports,

pipe hanger