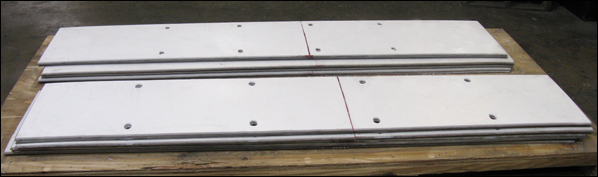

These custom designed pipe shoes were fabricated for main steam piping in a gold mine project. A total of forty-three pipe shoes ranging in size from 20" to 36" diameter were designed for temperatures up to 650°F. The shoes ranged in length from 17" to 24", width from 20" to 32" and height from 3" to 7". They are manufactured from carbon steel and have a two-coat paint system to protect against corrosion.

The Pipe Support Blog

Justin L

Recent Posts

Tags: Pipe Shoes

251 variable furnace springs were designed and fabricated for fertilizer production at a chemical plant in Virginia. The furnace cans are carbon steel and painted with red-oxide primer to avoid any potential hazards where exposed to high temperatures. This project included figures: PTP-1-120, PTP-2-150, PTP-2-180, PTP-4-100 and PTP-4-200 variable furnace springs with operating loads ranging from 1,042 lb. to 15,512 lb. A load test on all variable springs was conducted prior to shipment.

Tags: furnace spring, Variable Spring Support Assemblies, Variable Spring Hangers

Variable Springs with Guided Load Columns and PTFE Lined Pipe Saddles

These F-type variable spring supports are fabricated from carbon steel with a hot dipped galvanized finish and designed with guided load columns to provide stability for minimum lateral movement. The fig. 46 pipe saddles are also fabricated from carbon steel with a HDG finish and lined with PTFE, 25% glass filled material. The pipe saddles are designed for 8" to 36" diameter pipe sizes, and the entire assembly is 50" in height. These variable-saddle support assemblies are capable of supporting up to 22,300 lb. and 1" vertical movements. We performed standard spring loading tests and a Q.C. inspection prior to shipping to an offshore oil and gas platform near Malaysia.

Do you have a need for variable spring supports in your plant? Let us price them for you today!

Slide plates are easy to maintain if you follow these certain steps when inspecting them. Visit our visual media section to learn what four steps to take for Slide Plate Inspection and Maintenance. Our field service manager, David Baker, will show you what to look for when inspecting your PTFE slide plates. If you have any questions, feel free to call David Baker at 713-992-7048 or email us at info@pipingtech.com.

Tags: slide bearing plates, Slide Plates

These 200 U-Type constant spring supports were modified to increase their installed height by adding a secondary plate and angles, which will be welded to the structural beam. The constants range in size from 25" to 27" in height, 52" to 67" in length, and 25" in width. Their load capacities range from 10,300 lb. to 13,000 lb. with vertical movement ranging from 3" to 4-1/2". All constants were fabricated from A-36 carbon steel, and went through standard load and travel testing per MSS Standards prior to shipment. Do you have a similar application that requires upthrust constants? Get pricing today!

Yoke U-Bolt Pipe Clamps for a Continuous Catalyst Regeneration Plant

These custom heavy duty Fig. 43 yoke u-bolt pipe clamps are designed for manifold piping in a Continuous Catalyst Regeneration plant in Mexico. The yoke clamps are for a 36" diameter pipe size and are fabricated from A240 Grade 316 stainless steel. They are designed to support a load of 33,731 lb. and temperatures up to 1100°F. PT&P supplied a total of 16 assemblies, comprised of yoke u-bolt clamps and E-type constant springs, for this project.

Do you need yoke u-bolt clamps or constants? We would be happy to provide you with a quote today.

Do you have a plant turnaround coming up and need expansion joints?

Do you have a plant turnaround scheduled or planning one in the near future? PT&P is prepared to be there for you throughout the entire process. From planning, to execution, and follow-up, we have what it takes to accomplish a successful plant turnaround.

Prior to Your Turnaround: - Call our field service team to assist with plant walk-downs to assess your plant for maintenance, repair or replacement of pipe supports and expansion joints - Contact our quotations department for immediate pricing on pipe supports, expansion joints, or auxiliary steel needed during the turnaround. - Consult our experienced engineers for guidance on support placement, materials, finishes, etc. to ensure optimum life of the supports.

During Your Turnaround: - Use our field service team to guide you through installation, start-up, and replacement to safely and efficiently handle your turnaround. - For quick delivery, PT&P stocks over 1500 bellows, over 100,000 lb. of insulation materials, over 30,000 spring coils, and over 1 million pounds of standard items

Post Turnaround: - Receive training to monitor the supports, and identify potential failure, in order to prevent unplanned turnarounds in the future. - Learn correct size and selection of pipe supports and expansion joints per application for any post-turnaround resolutions. - Call on our field service team to develop a data book of existing pipe supports and expansion joints and their conditions in order to identify potential maintenance issues in upcoming turnarounds.

A rectangular metal expansion joint was refurbished on an emergency basis for a local chemical plant. Upon arrival, it was acid washed and dye-penetrant examined for any cracks. View the full Article

U.S. Bellows, Inc. refurbished two pressure balanced elbow expansion joints with a quick turnaround for a power generation plant during outages. They are designed for high pressure turbine crossover piping. The first 54" outside diameter expansion joint leaked from a crack in the bellows causing an unscheduled outage. View the full article.

This expansion joint was received in the morning and shipped to the customer the very same day. The bellows, liner and cover were replaced and the carbon steel parts were sand blasted, cleaned and painted. A dye-penetrant test and hydro-test to 518 PSIG were performed prior to shipment. View the full article.

This expansion joint was received in the morning and shipped to the customer the very same day. The bellows, liner and cover were replaced and the carbon steel parts were sand blasted, cleaned and painted. A dye-penetrant test and hydro-test to 518 PSIG were performed prior to shipment. View the full article.

This expansion joint was received in the morning, refurbished by adding new bellows and limit rods, and then shipped the very same day. New 321 stainless steel bellows were fabricated and the existing flanges were reused by sandblasting and then painting for corrosion protection. View the full article.

Let us assist you on your next plant turnaround. Our field service team is ready to help!

Tags: Pipe Support Field Services, Field Services, emergency

PTFE, 25% Glass Filled Slide Plates Bonded to Steel Backing Plates

The slide plates are comprised of 1/4" thick PTFE, 25% glass filled slide plates bonded to 1/8" A240 grade 316 L stainless steel backing plates. Stainless steel was used for better resistance to corrosion and longevity. The assemblies measure 83" long by 20" wide and will be installed underneath a bridge. A total of 16 slide plates were fabricated and designed for a pressure of 500 psi at ambient temperature. PTFE, 25% glass filled material provides a low coefficient of friction, is easy to install, does not require surface treatments, or grouting, and is unaffected by weather conditions.

Would you like to learn more about slide plates? Check out a recording of our past slide plate webinar!

The ladders and platforms were designed to be installed on a 90' tall pressure vessel. The ladders were fabricated from carbon steel and ranged in size from 5' to 38' in length. The vessel platforms were also fabricated from carbon steel and measure up to 16'-6" in diameter.

Do you require ladders or platforms for a vessel or tank? Let us serve your needs today!

Tags: ladder, platform, Pressure Vessel, ASME/Miscellaneous Fabrication

Subject: Constant Spring Supports Design and Application ** Webinar is worth 1 PDH Credit for TX Professional Engineers This Webinar is over... visit www.pipingtech.com/webinar to view the recording.

This Webinar will focus on the different types of constant spring supports. Learn about the special features available, in addition to the design of a constant support. View how the different cam/coil configurations produce a unique response to an applied load. Discover the step by step process used to size a spring for your application. Learn about the different attachments, testing, and installation and maintenance procedures. View examples of failed supports provided by our Field Service Division and learn why they failed and how to prevent it. Gain knowledge of the valuable tips used when deciding to adjust or replace a constant spring support, as well as shutdown and isolation procedures. The featured presenter, Jerry Godina has over 13 years experience as a pipe support designer and manages PT&P's engineer training development program. He also inspects existing supports, consults on site remediation projects and oversees installation on a regular basis.

Tags: Engineered Spring Supports, Constant Spring Supports, Constant Springs, Constants