PT&P Verifies New Designs for LNG Phenolic Base Support with Load Testing

Load Testing a Spring Support

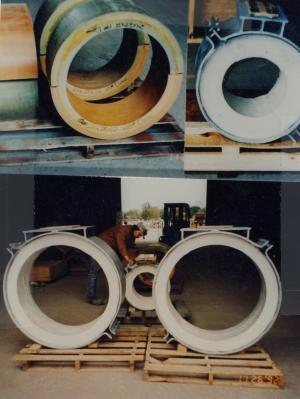

Piping Technology & Products, Inc. performs thorough product testing to verify new designs to a LNG Laminated Phenolic base support for an E&C company located in Houston, Texas. In order to determine the failure loads for a 30" diameter, pre-insulated shoes and a 6" diameter Laminated Phenolic base support respectively, PT&P performed lateral-load and axial load tests. The load tests performed ensure the pre-insulated pipe shoes can safely sustain the specified design load. The insulated shoes tested for the E&C company will be in service in 2001 at Atlantic LNG, where they will be used to support the liquid nitrogen gas (LNG) lines.

Big Ton Springs Installation Guide

1. Measure the existing installed load setting height to make sure that the big ton spring will fit tightly into the space provided. Shim from below as needed to ensure proper fit.

2. Place the big ton spring in the designated location, making sure that all required slide plates, shims, or auxiliary steel are in their proper positions.

3. Travel stop bolts can be released after all testing has been done. The travel stops are painted red and located on each end of the big ton spring. Follow the steps below to release the travel bolt stops. Please refer to the drawings to the left.

(a) Turn the nut on travel stop bolt No. 1 one-half turn; repeat on bolts 2 through 4.

(b) Repeat in this sequential order until the load is released. The load has now been transferred to whatever the big ton spring is supporting.

4. CAUTION: Be sure that the nuts on the travel stop bolts are backed off enough to accommodate the appropriate travel (Example: 1 inch of travel - the nuts should be backed off by 2 inches from the bottom of the travel stop plate.)

5. At this time the Lifting Eye Bolts may be removed.

Tension SystemsIn some cases, a straight line system of axial bellows anchors and guides is not practical or desired; or there is no reasonable way/ place to anchor the bellows thrust loads. In such cases self restrained bellows assemblies may be used, such as the double hinge restrained bellows shown below. Thermal expansion (or contraction) in the long pipe is absorbed by an offset deflection of the double hinge assembly. Bellows thrust load is carried by hinge bars, gimbals, tie rods or other such devices; hence normal tension is maintained in the pipe system and main anchors and full lateral restraint guides are unnecessary.