Do you have a plant turnaround scheduled or planning one in the near future? PT&P is prepared to be there for you throughout the entire process. From planning, to execution, and follow-up, we have what it takes to accomplish a successful plant turnaround.

Prior to Your Turnaround: - Call our field service team to assist with plant walk-downs to assess your plant for maintenance, repair or replacement of pipe supports and expansion joints - Contact our quotations department for immediate pricing on pipe supports, expansion joints, or auxiliary steel needed during the turnaround. - Consult our experienced engineers for guidance on support placement, materials, finishes, etc. to ensure optimum life of the supports.

During Your Turnaround: - Use our field service team to guide you through installation, start-up, and replacement to safely and efficiently handle your turnaround. - For quick delivery, PT&P stocks over 1500 bellows, over 100,000 lb. of insulation materials, over 30,000 spring coils, and over 1 million pounds of standard items

Post Turnaround: - Receive training to monitor the supports, and identify potential failure, in order to prevent unplanned turnarounds in the future. - Learn correct size and selection of pipe supports and expansion joints per application for any post-turnaround resolutions. - Call on our field service team to develop a data book of existing pipe supports and expansion joints and their conditions in order to identify potential maintenance issues in upcoming turnarounds.

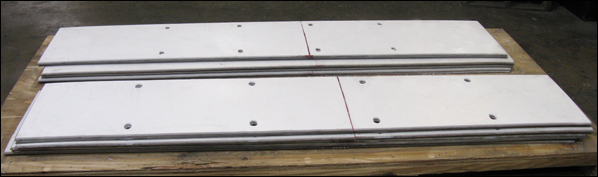

A rectangular metal expansion joint was refurbished on an emergency basis for a local chemical plant. Upon arrival, it was acid washed and dye-penetrant examined for any cracks. View the full Article

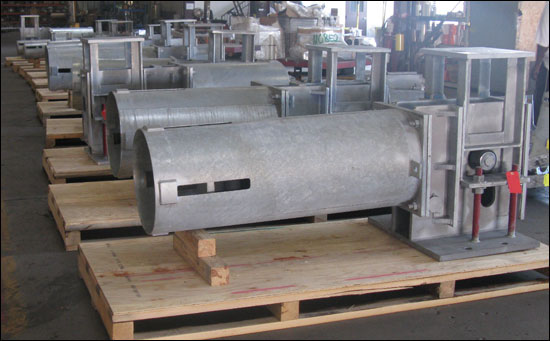

U.S. Bellows, Inc. refurbished two pressure balanced elbow expansion joints with a quick turnaround for a power generation plant during outages. They are designed for high pressure turbine crossover piping. The first 54" outside diameter expansion joint leaked from a crack in the bellows causing an unscheduled outage. View the full article.

This expansion joint was received in the morning and shipped to the customer the very same day. The bellows, liner and cover were replaced and the carbon steel parts were sand blasted, cleaned and painted. A dye-penetrant test and hydro-test to 518 PSIG were performed prior to shipment. View the full article.

This expansion joint was received in the morning and shipped to the customer the very same day. The bellows, liner and cover were replaced and the carbon steel parts were sand blasted, cleaned and painted. A dye-penetrant test and hydro-test to 518 PSIG were performed prior to shipment. View the full article.

This expansion joint was received in the morning, refurbished by adding new bellows and limit rods, and then shipped the very same day. New 321 stainless steel bellows were fabricated and the existing flanges were reused by sandblasting and then painting for corrosion protection. View the full article.

Let us assist you on your next plant turnaround. Our field service team is ready to help!

This presentation is on Pipe Clamps, including Hold-Down Clamps, Riser Clamps, Clevis Hangers, Yoke U-Bolt Clamps and Structural Supports. Learn how the appropriate type of pipe support is chosen based on the different design conditions. Find out how Finite Element Analysis is used in the design process and view the custom pipe supports designed for extreme applications. Finally, view the value-added services offered by PT&P and rest assure that your pipe clamp needs can be covered by our 24x7 web-based emergency services, field services and quick-turn around time when you need it most. The featured presenter, Jerry Godina has over 13 years experience as a pipe support designer and manages PT&P's engineer training development program. He also inspects existing supports, consults on site remediation projects and oversees installation on a regular basis.

This presentation is on Pipe Clamps, including Hold-Down Clamps, Riser Clamps, Clevis Hangers, Yoke U-Bolt Clamps and Structural Supports. Learn how the appropriate type of pipe support is chosen based on the different design conditions. Find out how Finite Element Analysis is used in the design process and view the custom pipe supports designed for extreme applications. Finally, view the value-added services offered by PT&P and rest assure that your pipe clamp needs can be covered by our 24x7 web-based emergency services, field services and quick-turn around time when you need it most. The featured presenter, Jerry Godina has over 13 years experience as a pipe support designer and manages PT&P's engineer training development program. He also inspects existing supports, consults on site remediation projects and oversees installation on a regular basis.