These custom designed pipe shoes were fabricated for main steam piping in a gold mine project. A total of forty-three pipe shoes ranging in size from 20" to 36" diameter were designed for temperatures up to 650°F. The shoes ranged in length from 17" to 24", width from 20" to 32" and height from 3" to 7". They are manufactured from carbon steel and have a two-coat paint system to protect against corrosion.

The Pipe Support Blog

Tags: Pipe Shoes

Subject: Pipe Clamp Design, Application & Installation

Register for 10:00 am CDT or 2:00 pm CDT (Thur. April 19, 2012)

Tags: Clamps, Clamp, Pipe Clamp Assembly, Riser Clamp, Yoke Clamp, Clevis Hangers, Yoke U-Bolt Clamps, Pipe Clamps, Riser Clamps, Hold Down Clamps, 3-Bolt Clamp, Pipe Clamp, 3-bolt Pipe Clamp, 3-bolt pipe clamps, clevis hanger, Clamp Assemblies, Clamp Assembly

251 variable furnace springs were designed and fabricated for fertilizer production at a chemical plant in Virginia. The furnace cans are carbon steel and painted with red-oxide primer to avoid any potential hazards where exposed to high temperatures. This project included figures: PTP-1-120, PTP-2-150, PTP-2-180, PTP-4-100 and PTP-4-200 variable furnace springs with operating loads ranging from 1,042 lb. to 15,512 lb. A load test on all variable springs was conducted prior to shipment.

Tags: furnace spring, Variable Spring Support Assemblies, Variable Spring Hangers

Subject: Pipe Supports and Expansion Joints for Furnace Applications

This Webinar is over, visit www.pipingtech.com/webinar to view the recording.

Tags: variable furnace springs, Expansion Joints, constant furnace springs, furnace bags

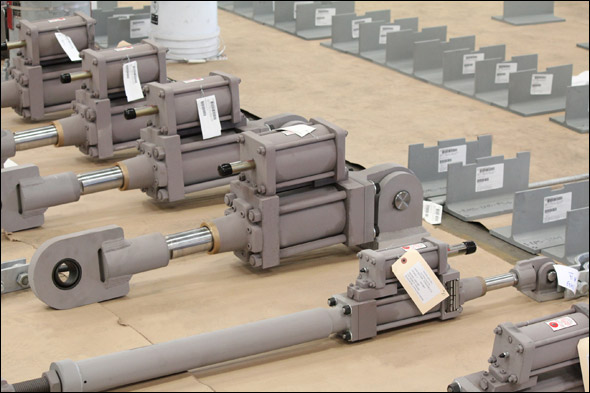

Fronek Anchor/Darling Enterprises, a division of PT&P designed and fabricated hydraulic snubbers for a geothermal facility in California. The Fig. 510 AD snubbers ranged in size from 34-3/4" to 37-5/8" piston-to-piston and were designed for a 50,000 lb. maximum load, 5" cylinder size and a 6" stroke. The Fig. 511 AD snubbers ranged in size from 56-15/16" to 59-5/16" P-P and were designed for a 20,000 lb. maximum load, 2-1/2" cylinder size and a 6" stroke. Hydraulic snubbers are designed to protect the piping system when a sudden, heavy load is applied (such as an earthquake of high intensity), which can cause serious vibrations leading to complete destruction. A custom three-bolt pipe clamp fabricated from carbon steel was designed to fit in a limited space. A cycle test throughout the full stroke from zero to fully extended was performed prior to shipment.

Tags: Snubbers, Hydraulic Snubbers

Follow these 7 steps below to maintain and extend the life span of your hydraulic snubber.

1. Observe the fluid level to make sure there is sufficient fluid for the snubber to operate

2. Check for leaks - If the fluid level is decreasing, determine the cause and effect remedial action.

3. Check the condition of the load pins and spherical ball bushings. Apply a high pressure grease for long-term benefits.

4. Check the condition of the exposed portion of the piston rod. Check for scoring, paint or other physical damage.

5. Check the condition of the piston rod wiper. Verify that it's in position and working effectively.

6. Check for evidence of abuse like welding arc strikes, bent or dented parts, scratched paint, etc.

7. Finally, check the overall physical appearance. This encompasses all of the above.

Subject: Shock Control, Restraint & Support Devices

** Webinar is worth 1 PDH Credit for TX Professional EngineersThis Webinar is over. Visit www.pipingtech.com/webinar to view the recording.

Explore the various applications of snubbers, sway braces and sway struts in piping systems and equipment. Learn how these products help prevent pipe system failure due to seismic loads, flow transients, wind loads, safety valve thrust loads or pipe rupture. Discover the various tests performed within PT&P’s facility to ensure product quality, including cycle testing, travel testing and load testing. Finally, view the value-added services offered by PT&P and rest assure that your shock control, restraint and support device needs can be covered by our 24x7 web-based emergency services, field services and quick-turn around time when you need it most.

Explore the various applications of snubbers, sway braces and sway struts in piping systems and equipment. Learn how these products help prevent pipe system failure due to seismic loads, flow transients, wind loads, safety valve thrust loads or pipe rupture. Discover the various tests performed within PT&P’s facility to ensure product quality, including cycle testing, travel testing and load testing. Finally, view the value-added services offered by PT&P and rest assure that your shock control, restraint and support device needs can be covered by our 24x7 web-based emergency services, field services and quick-turn around time when you need it most.Tags: Mechanical Snubbers, Hydraulic Snubbers, Sway Struts, Sway Braces

A total of eight big ton spring supports, "mega tons" were designed and manufactured to support two reactors in a power plant weighing approximately three million pounds each. The mega ton pictured incorporated eighteen individual spring coils to produce a load capacity of approximately 602,000 lb. and a spring rate of 112,500 lb./in. It was designed with eight Bronzphite® slide plates that measured 12" x 12". The 12" x 12" slide plate selection was based upon the ability to position individual squares across the load flange surface while simultaneously providing the total slide plate surface area required to support the operating loads. By using individual slide plate squares, the fabrication and assembly time was reduced because a standardized mounting procedure could be incorporated and repeated as necessary for each big-ton load flange subassembly. Overall, the slide plates were incorporated into the design to reduce the horizontal forces which would be imparted onto the big-ton spring's load flange during lateral deflection (movement) of the reactor.

Bronzphite® slide plates, in particular, were selected because these big-tons will be used in a location which will see continuous "cold-to-hot" operating cycles and as a result, the robust nature of Bronzphite® proved more advantageous than other types of slide plates. The other two designs used nine slide plates, one with fifteen individual coils to produce a operating load of 594,000 lb. and a spring rate of 250,050 lb./in. The other design had an operating load of 300,000 lb. and a spring rate of 106,000 lb./in.

Do you have a need for mega-tons like those described above? Get pricing today!

Tags: Big Ton Spring Supports, mega-tons

Variable Springs with Guided Load Columns and PTFE Lined Pipe Saddles

These F-type variable spring supports are fabricated from carbon steel with a hot dipped galvanized finish and designed with guided load columns to provide stability for minimum lateral movement. The fig. 46 pipe saddles are also fabricated from carbon steel with a HDG finish and lined with PTFE, 25% glass filled material. The pipe saddles are designed for 8" to 36" diameter pipe sizes, and the entire assembly is 50" in height. These variable-saddle support assemblies are capable of supporting up to 22,300 lb. and 1" vertical movements. We performed standard spring loading tests and a Q.C. inspection prior to shipping to an offshore oil and gas platform near Malaysia.

Do you have a need for variable spring supports in your plant? Let us price them for you today!

Slide plates are easy to maintain if you follow these certain steps when inspecting them. Visit our visual media section to learn what four steps to take for Slide Plate Inspection and Maintenance. Our field service manager, David Baker, will show you what to look for when inspecting your PTFE slide plates. If you have any questions, feel free to call David Baker at 713-992-7048 or email us at info@pipingtech.com.

Tags: slide bearing plates, Slide Plates